21.09.2021

More than 60,000 surgical masks recycled in France!

From February 2021, French employees of Hager Group have been able to recycle their surgical masks. These masks been transformed through an innovative recycling chain, the only one of its kind in France. Working to protect the environment.

Since the start of the pandemic, providing and wearing masks has been at the forefront of our efforts to keep our employees healthy. To limit our environmental impact as much as possible, as well as to follow our business vision, we’ve decided to work with a pioneer in recycling surgical masks in France, PLAXTIL.

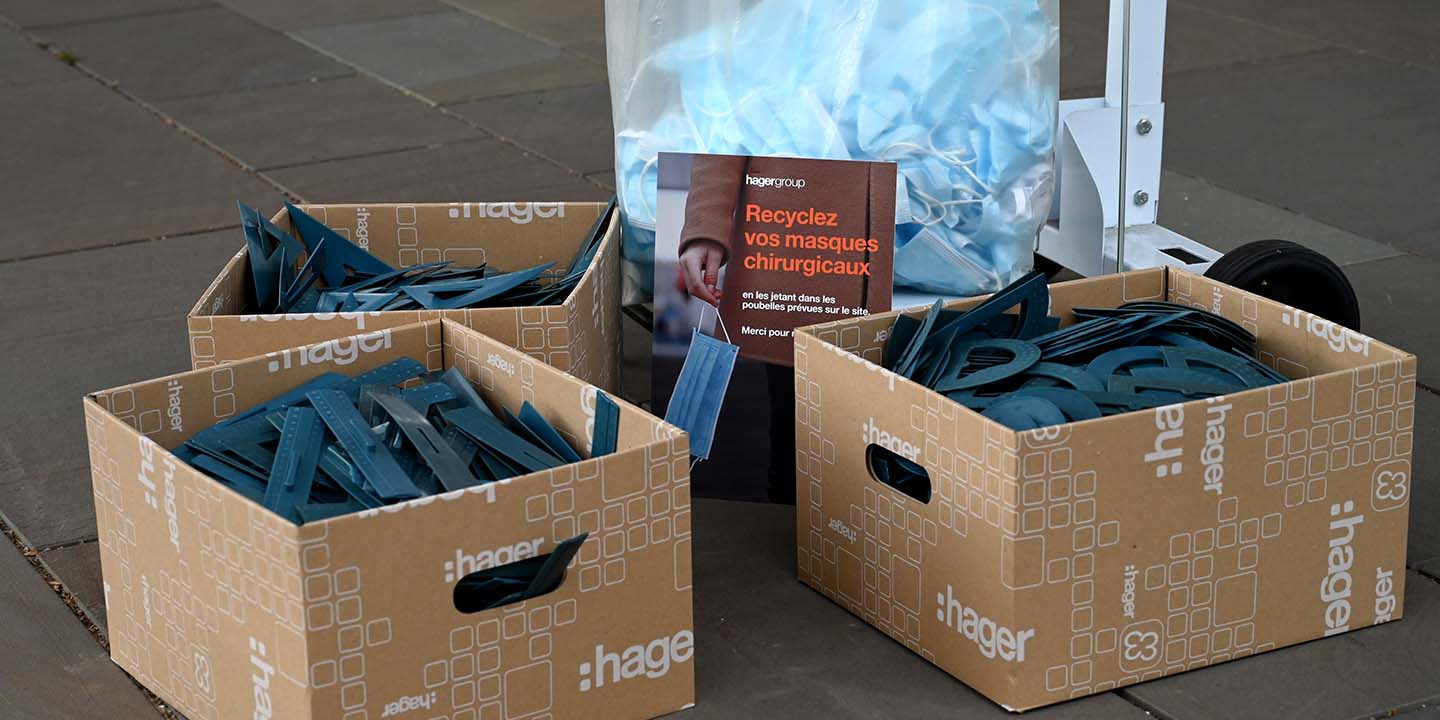

That’s why, in February this year, Hager Group rolled out the “Recycle Our Surgical Masks” campaign across all of our French production sites. Many of our employees took part and more than 60,000 surgical masks have already been collected. That’s 250 kilos!

Half of these have already been recycled. That means more than 500 school kits have been produced in just a few months, distributed by regional branches of Secours populaire français (French Popular Relief). They’ve since been handed out to the children of Strasbourg and its surroundings. The remaining half will be given out in the coming weeks.

“It really is a shared success and something we can all be proud of! These school kits are much more than simply mathematical instruments. They are the result of an innovative industrial initiative where we all work together for the environment. At Hager Group, these are the values we work towards every day,” said Gaetane Grange, Hager Group’s Sustainability & Environment Project Manager.

Surgical masks are made of non-biodegradable materials such as plastic (Polypropylene), elastic bands and metallic strips. These must first be separated. Founded in Vienna in 2020, the business then begins the process of cleaning, crushing and recycling. From these materials they make school geometry kits, including protractors, rulers and set squares. As these masks are essentially made from petrochemical products, it’s possible to change them into injectable polymers, thereby avoiding the use of any new plastic.

Other businesses have also been working in the region on this initiative, including the Schmidt Group, who we’ve been working with on delivering the masks to PLAXTIL.